GILSON History

My name is Nicholas Gilson, and I believe John Lennon said it best when he wrote, “Life is what happens to you while you’re busy making other plans.”

At the age of 14, my father was moved against his will from New Zealand to America in the hull of a steamship. His father had died years earlier, and his mother (my grandmother) had remarried an American Navy man.

Having been relocated to the landlocked state of Pennsylvania, my father longed to stay connected to his Kiwi roots, and in large part, that meant staying connected to sailing. He had built his first sailboat from a broom, sheet, and tire when he was five years old. My grandmother can be seen in an old photograph calmly watching her child venture out into the deep waters of Evans Bay in a small boat he had created. New Zealanders are the antithesis of the helicopter parent.

Now in America, my 14-year-old father started crafting his next boat, a project that would span generations.

2001

In 2001, some 40 years later, I was turning 13, and with the benefit of my father’s basement workshop, I too had developed a love for building and design. My Dad told me that when he was my age he had started to build a Paper Tiger, an iconic and ultralight wooden sailboat of New Zealand design. This explained the two large and unfinished boat hulls in the basement of my family’s home in Rhode Island; they had been there for as long as I could remember.

In 2001, my father had an idea rooted in nostalgia. I, his oldest son, was just about the age he was when he first began building the Paper Tiger, and I think I had finally started to impress him with my woodworking capabilities.

He suggested I pick up where he left off.

2002

By the summer of 2002, I was fully immersed in the Paper Tiger Project. My father slipped back into an unbridled obsession with the endeavor, and I benefited from a highly engaged mentor. Our free hours were spent together sanding, building, and fiberglassing. My father taught me the importance of geometry and fluid dynamics as he allocated a painstaking amount of attention to every

curvature and detail in the boat’s shape.

During the days, I was struggling through middle school. I loved math and science, but I couldn’t seem to learn as fast or in the same ways as the other students. My mind would often drift to the workshop and to the Paper Tiger, and increasingly, to surfboards and snowboards.

I developed a fascination for boardsports and the lifestyles they evoked. My grandmother on my mom’s side was a beautiful skier, and she passed that onto her kids and grandkids. Thanks to my mom and grandmother, I had been on the mountain since I could walk, and thanks to my Dad, I had been coaxed into sailboats only a short while after that, but I had never known anyone who could surf waves. I was completely mesmerized by the idea.

In an early lesson on the power of FedEx and the internet, I placed an order online from a wholesaler for a block of polystyrene foam, a roll of fiberglass, and a bucket of epoxy. Next to the Paper Tiger, I started my own project. I figured that if I could teach myself how to make a surfboard, I could learn to surf. This turned out to be true.

While there was no Hollywood-style eureka moment, it was at this time, with all of these things on my mind, that our modern day design approach got its start.

I remember sitting in science class gazing at the scribbled chalk marks denoting H2O(solid) and H2O(liquid) on the board. Our teacher was explaining phase changes, or something of the sort. Although it is hard to be sure looking back so many years later, I believe it was in this moment that I made the initial connections between water and snow -- between sailboats, surfboards, and snowboards.

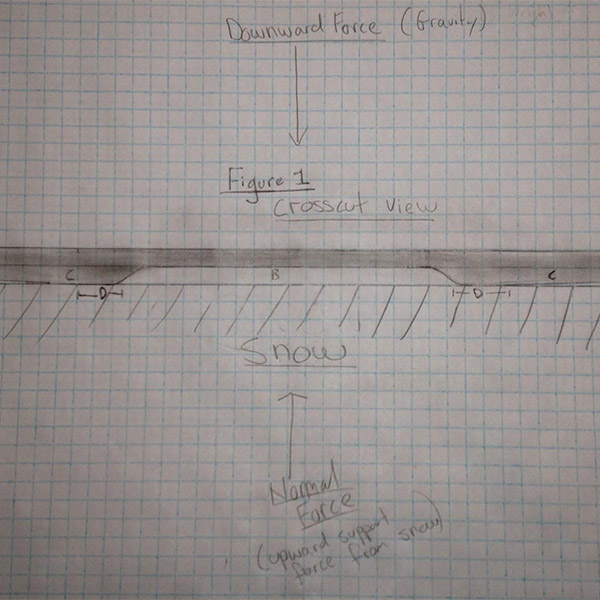

A question fixed itself in my mind: if snow and water are the same molecule in different states, why is there no attention given to geometry and fluid dynamics in snow, but so much attention in water?

Snow, especially softer snow, should act like a fluid when in motion, so why are snowboards and skis flat while every other moving object benefits from curvature? Boats, planes, cars, submarines -- they are all carefully designed and carefully curved. So are dolphins, fish, and birds, by the way.

2003

By the spring of 2003, I was 14 years old and the initial concepts had begun to crystallize in my mind. The Paper Tiger had been painted, rigged, and christened, and my dad and I had taken our maiden voyage. The boat was a blast to sail. It cut through the water with unparalleled precision and elegance. We had nailed the fluid dynamics.

Having taught myself how to shape and fiberglass, I was now also the proud owner of my first surfboard. I implemented my early fluid dynamics thinking into that design, but curving surfboards for performance wasn’t exactly revolutionary; it was standard practice. Every surfer knows you don’t want the bottom of your board to be perfectly flat -- what a wasted opportunity that would be.

I taught myself to paddle out and ride waves, and I fell completely in love with the ocean all over again. What an amazing force. What an incredible amount of energy. Something to be loved and feared and respected at the same time.

I similarly revere my father, and at that early age I still expected him to have all the answers to the world's questions. I asked him why no one cared about fluid dynamics and geometry in snow when it clearly mattered. We talked about how he would always kick my butt when we raced down the mountain. We acknowledged the mass differential, he was still heavier than me, but it didn’t matter: skiers were simply faster than snowboarders. Turns out, “wetted surface length” and “wetted surface width” matter on snow too. Snowboards were like fat little sailboats, and skis were like the Paper Tiger: long, narrow, and twin-hulled. Most importantly, there was no observable reason for why snowboards had to be so limited.

That spring, for my 8th grade school project, I set out to build my first snowboard prototypes.

My father, once again, was my thought partner, and he was instrumental in thinking through the design challenges. Snowboards, unlike surfboards and boats, need to be pressed as the fiberglass cures. Before I could build the first fluid-dynamics inspired snowboard, I had to build a press.

I found two old doors in our basement, and by screwing blocks of wood into them in corresponding locations, I could force a plank of wood to bend into a snowboard shape by clamping the two doors together with the materials sandwiched in between.

I built the first two GILSON Snowboards that year. I also built two flat snowboards as a control; it wouldn’t be fair to test my 14 year old capabilities against the biggest players in the industry and their foreign manufacturing facilities. I was building with wood and surfboard fiberglass, and they were building with high density plastics that were designed to hold wax and slide on snow.

I could tell you my first two prototypes worked, but I am as biased as they come and I am the only one who rode them, so I wouldn’t take my word for it anyway.

I now know the results were inconclusive, but it was clear that these early boards were unlike anything anyone had seen before. They looked different and they felt different. To me, it looked like I had shrunk the Paper Tiger and glued it to the bottom of a wooden snowboard.

2003-2011

I had done alright on my 8th grade project and somehow managed to sneak out of my middle school years. Despite figuring out how to build the earliest prototypes, my 14-year-old mind was not equipped for what would be required next.

The idea was cast to the back burner, although not for lack of effort. I got laughed out of a patent lawyer’s office as a young teenager for assuming patents were free, and in my parents’ basement, I deconstructed industry standard snowboards and attempted to rebuild them with fluid-dynamics inspired designs. This initiative ultimately came to a halt when I nearly set fire to my childhood home. I was holding a stick of burning plastic as flaming balls of the material were uncontrollably flung over the sawdust-ridden floor.

The design approach never left my mind, though, and at some point during my teenage years, I recall being stuck on a plane as a whole new set of realizations came flooding in. I asked my neighbor for a pencil and paper and for the duration of the flight I ferociously drew blueprints and scribbled down notes about the potential designs and their corresponding benefits on snow. I don’t remember his name or what he looked like, but at some point my neighbor, to whom the pencil and paper belonged, asked me what on earth I was doing. I must have been a strange sight. I paused and looked up, thinking about how I had no patent protection. I couldn’t contain myself. I told this perfect stranger that if he promised never to tell anyone, I would explain my thinking. He laughed and agreed. He was the first person outside my closest circle to know and understand this approach to snow design, although I doubt he appreciated its true potential. I wonder where he is now. I am thankful he kept his word.

2011

By 2011, the idea was at its lowest ebb. Despite a brief effort to compile my fluid-dynamics materials and educate myself on patent law, the idea barely surfaced in my mind.

That spring, I graduated from Johns Hopkins University. I accepted an assignment to move to Nashville, Tennessee to teach Middle School Science with an organization called Teach For America.

The humor is not lost on me that despite my efforts in high school and college, I would have to return to middle school to realize this idea.

That fall, I was confronted with the biggest challenge of my life to date, and for the first time, the spoils of victory and the burdens of failure did not fall on me. My 80 students now carried the weight of my success and failure, and we had much ground to cover.

My students were a motley crew. A student reading on a college level sat next to a student on a 3rd grade level. In the next couple of chairs, I had a student learning English and another asking me theoretical physics questions about objects entering black holes from different reference frames. We were all over the map, and that was a big problem. This incongruous mixture was a teacher’s worst nightmare. One lesson plan and one teacher couldn’t address all of the needs of the classroom.

And now for the really bad part: in aggregate, we were testing at 18% proficiency.

Around this time, I met someone who would become one of my greatest thought partners. Austin Royer joined our school as the 7th and 8th grade science teacher. He told me he was a woodworker, but I assumed that just meant he had built a tree house with his dad or something. I didn’t take him seriously.

Spring 2012

In the spring of 2012, I was working over 100 hours per week. I didn’t stop. Even cooking took too long. I bought a rice cooker, and each night, I filled it with grains of rice and frozen vegetables and turned the machine on so I could work while my automated food cooked. A half hour later, the machine would ding, and my fuel for the next 24 hours would be ready.

Through brute force, we made gains during that first year, but it wasn’t enough.

I don’t remember when, but at some point that spring I went to Austin’s house in Nashville. As I stepped into his home, my jaw dropped. I had never seen anything like it. The table, the chairs, the wardrobe, the… everything. Solid wood and stunning. No one builds like this anymore. You can’t find stuff like this anywhere. It's priceless. Astonished, I asked him where he got all of this furniture. He looked confused. “What do you mean? I built it.”

I sank into Austin’s couch humbled by his abilities.

September 2012

By the fall of 2012, Austin and I had come to the conclusion that if we were to succeed, we desperately needed each other.

We agreed that brute force had gotten something done, but it wasn’t enough. We were coming up against the same historical ceilings to growth: there is only one teacher in each room and only so many hours in the day.

We knew that we couldn’t address all the needs from the front of the classroom, so we abandoned the state-enforced guidelines and we wrote our own curriculum.

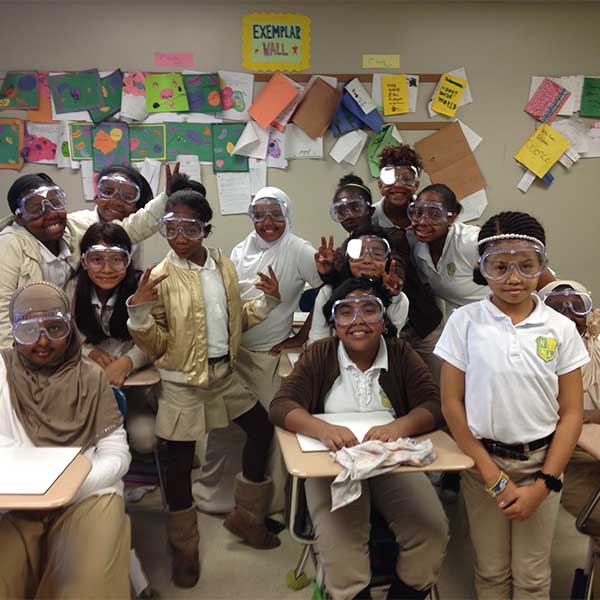

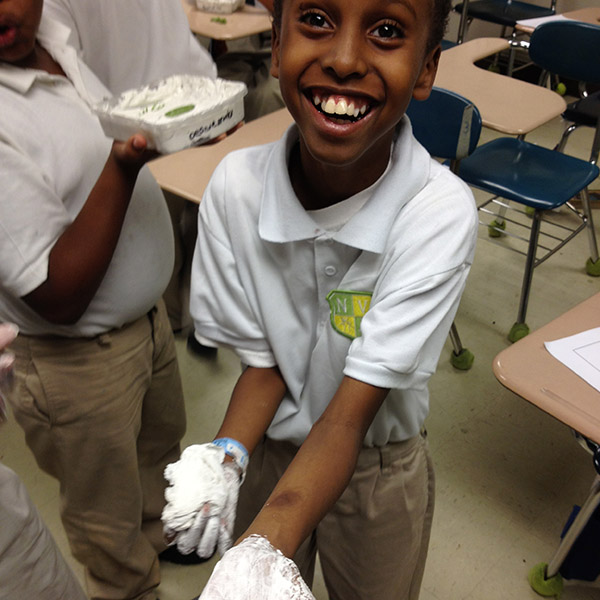

In an assessment of our available resources, like a soldier inventorying his rations behind enemy lines, we realized that the only other people who could help were our students. So we enlisted them to join the cause. We got rid of the typical teaching format and we committed fully to hands-on learning.

Our classrooms looked like total chaos. We were loud, we got dirty, and the only thing that was off-limits was wasting time. Through the apparent discord, students who were behind began learning from students ahead, and students ahead reinforced their thinking as they caught their peers up.

Adults, if you could call us that at 23, can be intimidating, and fear impedes learning. If, however, your friend invests in you like a teacher, all barriers crumble and all expectations rise.

A sense of unity enveloped us, and each individual became both a teacher and a student. At the time, our methods were odd at best, and banned at worst. We were reprimanded by the administrators and told to get our classrooms in order more times than we can recall, but our data told a different story. We were picking up speed.

October 2012

With growing confidence in our new methodology, we introduced the “Year Long Curiosity Project.” There were only two guidelines: first, your work had to be school appropriate, and second, you really, really had to care.

In an act of solidarity, Austin and I brought in the first snowboard prototypes that I had built when I was our students’ age. We told them that we too would be embarking on our own curiosity project.

We got carried away, to say the least.

Within weeks, we had drilled out the locked basement door in the home I was renting and we started to build a rudimentary snowboard shop in the crawlspace under the house.

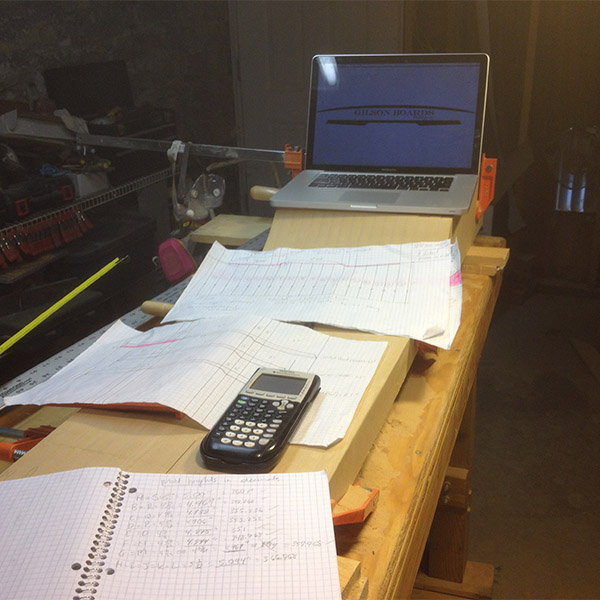

Austin and I created our first division of labor, something we would go on to do many times over the coming years. I focused on figuring out the fluid dynamics, and Austin tasked himself with building our first real snowboard press.

As our time spent in the shop increased, we told ourselves it was in the name of education, but I started to wonder if other intrinsic motivators weren’t creeping into the equation.

Each school day, we used our progress as an example to our students, and we involved them completely in our thinking. I don’t know if it was for them or for us. Perhaps both. They were really helpful.

November 2012

By mid November, our basement shop was defined by a massive object in the center of the room.

Austin had built his first press from lumber instead of steel because that’s what we could afford. As a result, in order to withstand the pressures we were about to apply, he determined that it needed to weigh at least a metric ton and be much larger than one might think. We would later learn that this was not overkill.

Around this time, in an event that can only be explained by serendipity, we met Adam Vanderhyden. He lived in Chicago and worked as a high level computer scientist -- one of the best -- and he was in Nashville on a chance visit with his wife. He was looking for something to do while she was preoccupied, so we enlisted his help in assembling the wooden behemoth. Within the year, Adam would build the first GILSON website, bring our fluid dynamics designs to the digital CAD space, and he would be the third founder on the company’s formation documents.

While Austin had been expanding his knowledge on heavy engineering, I had been meticulously shaping our first snowboard mold and preparing designs and materials for our first build.

Our press looked like a centipede with thick evenly-spaced wooden beams for legs. To deliver the pressure, Austin somehow acquired the inner tube from an earth-mover’s tire. I have since seen the vehicles to which these tires belong, and they make Monster Trucks look like Hot Wheels. A ladder is required to reach the driver's seat.

We slit the rubber and stretched it out into a long straight tube. We affixed metal brackets at the ends with silicone gel and bolts to seal the pressure. To restrain the volume, we wrapped the tube in a thick piece of fabric cut from a wedding tent and we stitched it together with a high-test tuna fishing line. We positioned the reinforced bladder in the wooden behemoth and hooked our small air compressor up to the tire’s air valve. We were finally ready.

November 12, 2012

It took us months to get to this moment. It had been a decade since I built the first prototype. People in the neighborhood had heard hushed whispers about our work, not because it was cool, but because it was strange. On the day we set to press our first snowboard, we came home from school to find a small gathering of people outside of our basement workshop.

With our hearts beating hard, and with a small audience crammed into the basement crawl space, we rehearsed every move we would make in the next 20 minutes. We knew that once we mixed the epoxy the chemical reaction would begin to take effect and the clock would start ticking. We needed to be at pressure in less than 20.

I don’t think we looked good doing it, but 19 minutes later, Austin and I scrambled to position our first snowboard inside the wooden behemoth -- on top of our mold and under the reinforced tube.

We turned on the compressor and as it rattled the bladder began to fill with air. The layers squeezed together and for the first time we watched a board take its shape under tremendous pressure. As the excess epoxy oozed out between the layers, Austin said, “Okay, the bag is full and our volume is maxed out. Let’s keep adding air and drive up the pressure.”

As we passed into double digit readings Austin murmured to me, “you know you can lift a house with five PSI if you put it in the right place.” The spectators that overheard decided to leave the crawl space and watch from outside. I don’t think the wooden behemoth in all its glory inspired much confidence. Austin turned the compressor off at 29 PSI and we cringed as the wooden beams creaked and bowed. Our back-of-the-napkin math estimated we now had 31,500 pounds of pressure over the board’s surface area.

That Night

Monday, November 12th to Tuesday, November 13th, 2012.

As the crowd dispersed to the local Nashville bar on 12 South, we did not feel any sense of relief. Without heat being added to the chemical reaction, it would take over 12 hours for the board to cure. We wouldn’t know how it went until the following day. Months of work and a decade of thought hung in the air like the sounds from a poorly tuned violin. I have never felt such anticipation so intimately intertwined with fear of failure and anguish.

In this moment, I admitted to myself that we had gone beyond the scope of the Curiosity Project and that I had become emotionally attached. Or perhaps I had always been emotionally attached.

Austin is not one to get excited; he is always calm and collected. In his naturally confident tone I heard him say from the other side of the room, “uh oh, we have a problem.”

I do not claim to have Austin’s emotional resolve. My heart began to race as it sank.

Austin is also incredibly observant. He had noticed the pressure reading on the compressor slowly slipping down. We had a leak, and the regulator wasn’t kicking the air back on automatically. Without human intervention every 15 minutes, our system would begin to deflate and the layers in our snowboard would peel apart.

I cleared the tools and sawdust off the workbench and got my sleeping bag from upstairs. I made a bed next to the wooden behemoth and pulled the compressor to within arms reach. I turned off the lights and set my alarm for 15 minute intervals.

December 2012

With two GILSON Snowboards now in existence, one deliberately different from the other, I reveled in our success with our students. My expectations soared. Austin remained realistic. Never pessimistic, but always realistic.

We booked a hotel room in Avon, Colorado and packed our bags and gear. My younger brother, James, booked a flight to meet us and help collect data. In the days leading up to the trip, our students designed scientific experiments for the mountains and we promised to collect data for analysis after the holidays. We were all on the edge of our seats.

January 2013

After the new year, I returned to school devastated.

With my tail between my legs, I loaded our data onto the projector. We had run the studies our students had designed. They were good studies, and they clearly demonstrated total failure. We also collected plenty of qualitative data -- Austin described the boards as, “trying to ride a canoe down the mountain.”

As I stood in front of that classroom, a feeling of paralysis overwhelmed my body. In that moment, I realized that I was witnessing months of work coming to a bitter end. To make it worse, I had an audience. Those feelings, though, paled in comparison to the realization that I had dedicated a decade of thought to something in vain.

My students were upset and Austin was having a similar experience down the hall. Inadvertently, we were showing our students what rock bottom failure looks like.

Somewhere behind the noise in my mind, I was telling myself that perhaps the design had failed, but the design-approach had not. Perhaps we had yet to discover the right geometry.

I don’t know which voice would have drowned out the other in the end, but a student named Cassius ensured there would be no mental battle.

I told my students that despite the failure in our project, they would still be responsible for their Curiosity Projects. I was met with a combination of blank stares and tears.

Cassius raised his hand. “Yes, Cassius?” I asked. After a long pause, Cassius said quietly, but assertively, “Mr. Gilson, if you can quit, we can quit.”

Silence. Nobody will humble you faster than a 6th grader.

2013

Our design had failed, but perhaps our teaching methodology had not.

As I returned to my blueprints with newfound energy, it occurred to me that our approach to teaching was more powerful than I had previously understood. We had set out to make each of our students also a teacher because we believed that would create a culture of unity and allow growth to accelerate... and also because we needed the help.

What I didn’t quite understand, is that I too was now a part of this team, and as Cassius made clear, the same rules applied to me.

- The 3D Edge was invented shortly after and was the key that unlocked the new approach to snowboard & ski design. The first three 3D Edge prototypes were pressed in the wooden behemoth in Nashville. She exploded at 40 PSI with no one in the shop. She was bearing the last Nashville Prototype and hung on long enough for the epoxy to cure and for us to get the data we needed.

- That May, when the standardized test rolled around, no one was scared. The results indicated that we had grown from 18% proficiency to 89% proficiency, making us the fastest growing science program in the district. The school went from being unranked to being in the top five, and we launched the company out of the classroom with our students.

- The first members of the GILSON Team moved to a cabin in the woods of Pennsylvania with no running water or electricity. We hiked out each day and built our first production facility in a donkey and horse stable that belonged to Austin’s family.

- That summer, we built a new press out of steel. We barely managed to build 35 artless black and white snowboards before the first snow. We purchased a 1976 Airstream and a truck with 212,000 miles on it. We loaded up the 35 snowboards and set out on a 17,000 mile road trip around the United States, now the annual GILSON Winter Tour.

- GILSON is now one of the fastest growing snowsports companies in the World, shipping snowboards and skis across North America, Europe, Australia, Asia and to my father's home country, New Zealand.